In global home and commercial electrical systems, electrical outlets are among the most basic yet most regionally significant electrical devices. Many newcomers to the UK notice a striking difference: UK Wall Sockets are not only larger and have a different design, but they also commonly feature a three-prong layout, include a switch, and have a unique safety structure.

In contrast, American wall sockets are smaller and typically use a two- or three-prong design with two parallel prongs. Therefore, many people ask:

Why are UK Wall Sockets so significantly different from American wall sockets? How did these differences arise? What electrical standards, design philosophies, and safety logics do they reflect?

This article will delve into these questions, analyzing the structural differences between UK Wall Sockets and American wall sockets from multiple dimensions, including voltage systems and national standards, and comprehensively explaining why UK Wall Sockets have taken on their current specific form.

Where does the design philosophy of the UK Wall Socket originate?

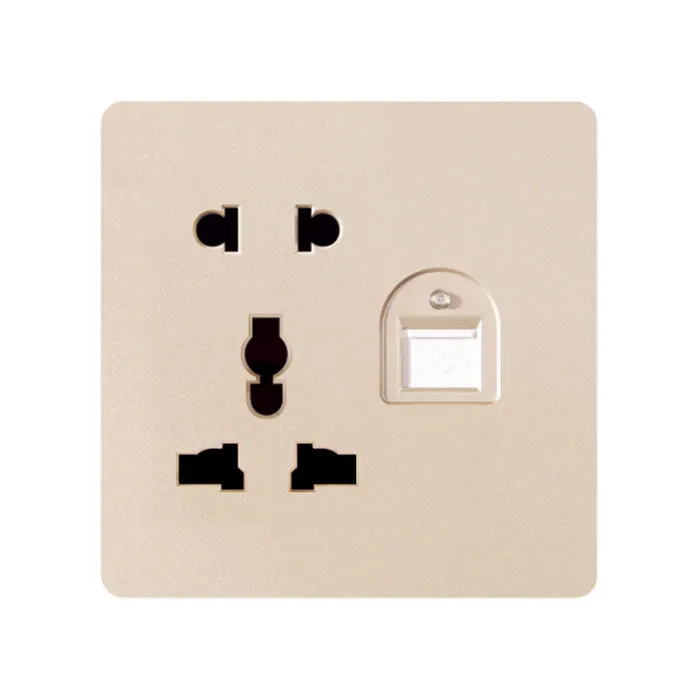

The UK Wall Socket is based on the BS 1363 standard, which strictly regulates the safety, size, plug structure, rated current, and contact layout of the socket. The core concepts of the UK Wall Socket include:

1. Prioritizing High Safety Design

UK Wall Sockets emphasize physical safety protection, child safety, prevention of accidental contact, and electrical isolation.

2. Adapting to 230V High-Voltage Systems

The UK electricity system uses 230V, requiring higher levels of insulation and safety measures.

3. Built-in Fuse in the Plug

The internal fuse design in the plug is a key feature of the UK electricity system, unlike American sockets.

4. Three-Prong Grounding Design

UK Wall Sockets use a three-prong structure, with the ground prong being longer to ensure safe contact.

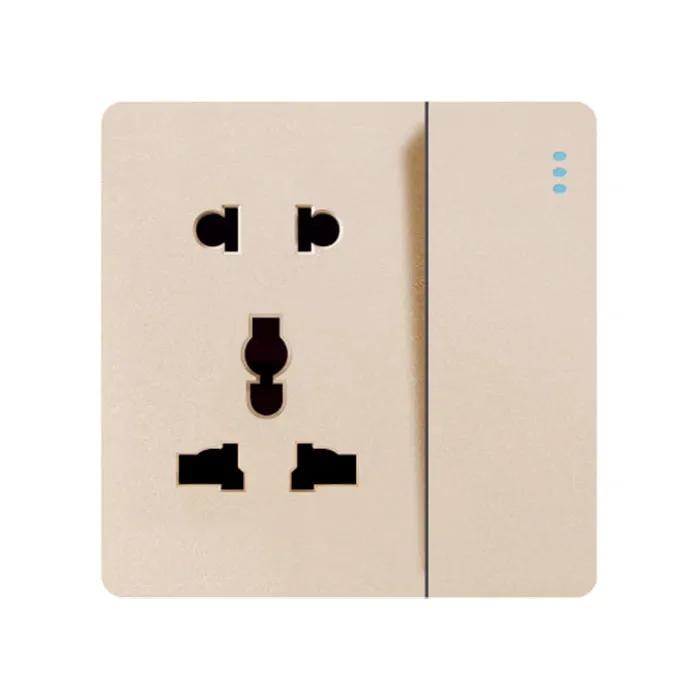

5. Commonly Includes a Switch

Many UK Wall Sockets have a built-in visible switch for controlling the socket's power status.

These concepts differ from American socket design standards, fundamentally leading to significant differences between the two.

Why does the UK Wall Socket use a three-prong design, while American sockets commonly have two prongs?

Many people's most immediate question is:

"Why must UK wall sockets have three prongs, while many American sockets only have two?"

The answer is closely related to the different countries' emphasis on grounding safety, differences in electrical system voltages, and plug specifications.

UK wall sockets must have a complete three-prong structure because:

1. The UK uses a 230V voltage system, which is higher

Higher voltage means a greater risk of leakage, short circuits, or electric shock, thus requiring more stringent grounding.

2. UK standards require plugs to have fuses, and sockets must be compatible

The design of UK wall sockets is designed to match the fuse structure of plugs, requiring a three-prong layout.

3. UK wall sockets incorporate a safety shutter design

The grounding prong triggers the safety shutter to prevent children or foreign objects from inserting into the live and neutral prongs.

In comparison:

• US sockets commonly use 120V voltage.

• Grounding is not mandatory for all sockets.

• Plugs are smaller.

• Sockets without safety shutters are more common.

Therefore, a three-prong layout is a necessary feature of UK wall sockets, resulting in larger and more complex sockets compared to American ones.

Why do UK wall sockets have switches, while American ones usually don't?

Another common question is:

"Why do almost all UK wall sockets have switches, while American sockets rarely do?"

This is one of the most obvious characteristics of UK wall sockets.

Reasons for UK wall sockets having switches include:

1. Using 230V, adding a manual power-off function improves safety

Cutting off the power before unplugging prevents arcing.

2. Wiring requirements of historic buildings

The electrical design of some older buildings requires additional local power disconnect devices.

3. User electricity habits

The British are accustomed to controlling the power of small appliances through wall sockets.

4. BS 1363 recommends, but doesn't mandate, its widespread use

This makes the physical characteristics of UK wall sockets even more distinct from American ones.

However, American sockets typically don't have switches because:

• American circuit design emphasizes central switches or circuit breaker control.

• Sockets are designed for simplicity, without switches.

• Different building wiring methods eliminate the need for power control at each socket.

This results in completely different operation between UK and American wall sockets.

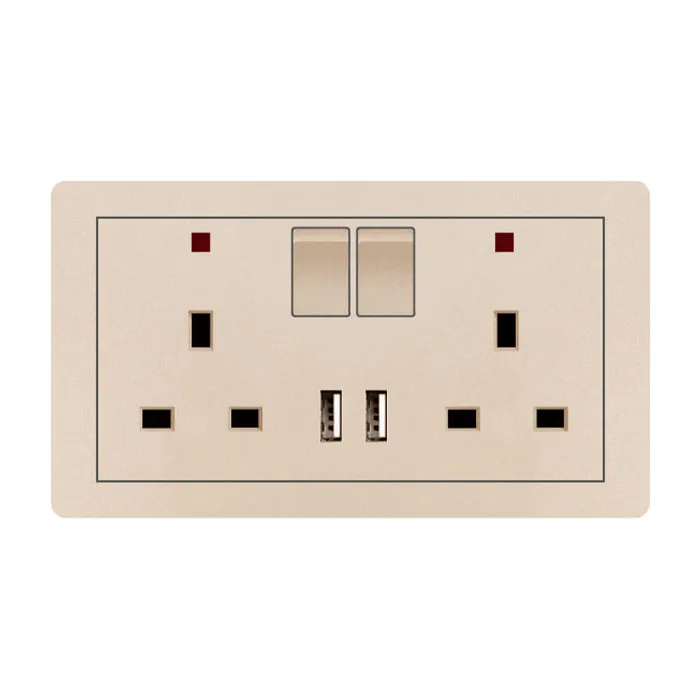

Why are UK wall sockets larger than American sockets?

UK wall sockets are significantly larger than American sockets. This is related to their structure, safety mechanisms, and internal space requirements.

The reasons for the larger size of UK wall sockets include:

• The three-prong layout takes up more space.

• It needs to accommodate a safety shutter mechanism.

• Many models are equipped with independent switches and indicator lights.

• Thicker internal copper contacts to accommodate 13A current and 230V voltage.

• The mounting box is usually deeper, and the wiring method is different.

American sockets, due to their simpler structure (two or three prongs), use 120V, have thinner copper contacts, and lack switches, resulting in a smaller overall size.

Why do UK wall sockets require stricter safety measures?

UK wall socket safety standards have always been very stringent, including:

• Socket safety shutters

• Plug fuses

• Three-prong grounding

• Larger spacing between live and neutral wires

• High heat-resistant materials

• Plugs must have fuses.

In contrast, American sockets prioritize lightweight design, cost, and traditional construction, thus showing a significant difference between the two. The reasons for emphasizing safety in UK Wall Sockets include:

1. Higher risk of electric shock under high-voltage systems

Historically, building wiring commonly used ring circuits, requiring additional safety measures.

2. British standards emphasize physical protection mechanisms

UK residential areas are generally densely populated, and standardized electrical systems necessitate higher safety levels.

From these perspectives, the focus on safety in UK Wall Sockets is inevitable.

Why do UK Wall Socket plugs have fuses?

This is one of the most important differences between UK and US socket systems.

Reasons for built-in fuses in UK plugs:

• Protect the connected device

• Protect the socket itself

• Prevent overload of the wiring

• Adapt to the characteristics of ring circuit wiring

This also results in UK plugs being much larger than American plugs, thus requiring more space for the corresponding UK Wall Socket.

American plugs do not have fuses, resulting in a simpler socket structure.

Why do UK Wall Sockets use different wiring methods?

The UK uses ring circuit wiring, while the US uses radial circuit wiring. These different wiring methods directly affect socket design requirements.

UK Wall Socket Wiring Characteristics:

• The same circuit starts from the distribution box, loops around, and returns to the distribution box.

• Current is split in two directions.

• Therefore, the socket must have a protection mechanism to prevent overload.

• Therefore, a plug fuse is indispensable.

American wiring methods are different, therefore the socket design follows a different logic.

Why do UK Wall Socket plugs face downwards, while American ones are more often upwards or horizontal?

UK Wall Socket plugs face downwards to:

• Reduce cable bending

• Protect the cable exit direction

• Prevent the plug from loosening due to gravity

• Facilitate switching and controlling power status.

American plugs are more flexible, can be inserted in multiple directions, and have different styles.

This further leads to a significant difference in the appearance of the two types of sockets.

What are the differences in rated power between UK Wall Sockets and American sockets?

• UK Standard: 13A × 230V = 2990W

• US Standard: 15A × 120V = 1800W

Therefore, the UK Wall Socket must be designed to be more robust and safer to withstand nearly 3000W of power, while US sockets only need to handle lower power.

This is one of the reasons why the UK Wall Socket appears "larger" and "more complex."

Why is the UK Wall Socket incompatible with US plugs?

The UK Wall Socket uses a three-prong square layout, while US sockets use a parallel prong layout, making them physically incompatible. Furthermore, the voltages are different, so direct insertion must be avoided.

This incompatibility is for user safety, not simply a difference in standards.

What after-sales services and warranties do you provide to buyers?

Zhongmei provides comprehensive after-sales support including product warranty, replacement for manufacturing defects within the warranty period, and technical assistance for installation or troubleshooting. As a supplier with in-house production, we streamline returns and repairs and work with purchasing teams to set clear warranty terms in sales contracts.

For wholesale clients, we can include extended support packages, spare parts supply, and priority production scheduling.